Welcome to

About us

As a privately-owned small-sized company, we are engaged in the manufacture of welded steel structures - mainly components for rolling stocks - with the addition of related engineering services. As a new player, we are aware that we need to offer our customers a higher level of service than our competitors in order to be successful in the long term in this narrow market.

SVEDY provides welded components with reliability and safety. But we also offer our customers much more than that: we make a considerable contribution to the growth of their competitiveness.

The key benefits of our streamlined, small organization - cost efficiency, flexibility and speed - all serve one purpose: to drive the market success of our customers and safeguard our growth and earning power.

OUR SERVICES

WE'RE NOT SATISFIED UNTIL YOU ARE

Design

from simple component drawings to more complex welded components design

Parts production

laser cutting, bending, turning, milling by subcontractors

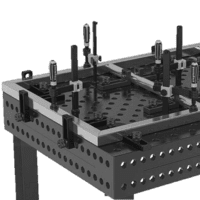

Welding

professional manufacture of simple and advanced welded structures for rolling stocks

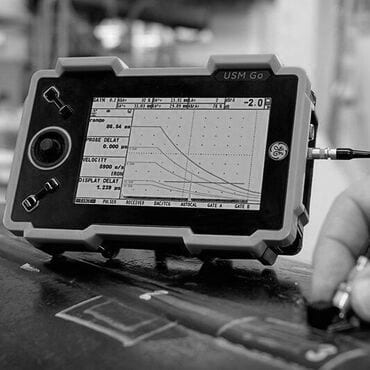

Non destructive testing

visual-, penetrant-, ultrasonic- and magnetic testing by subcontractors

Technical background

We use new 300A and 350A LORCH MicorMIG professional welding machines with excellent features to ensure the efficiency and flexibility of our production.

- Perfect welding results

- Compliant and combinable

- Future-proof & flexible

- Quality assurance with the authorisation concept

- Energy efficiency by technology

Quality Assurance

As a supplier to the rail industry, we can only ensure the safe movement of vehicles with impeccable quality. Sustainable quality is ensured through our robust quality management system, the reliability of which is partly proven by external certifications.

ISO 9001

ISO 9001

Our company's operations comply with the EN ISO 9001 standard.

Certification will take place in the first half of 2024

EN 3834

EN 3834-2

Our welding workshop meets the requirements of EN 3834-2 standard.

Certification was successfully done in October 2023.

EN 15085

CL1

EN 15085-2

We built and implemented processes according to EN 15085-2 standard.

Certification was successfully done in November 2023.

Manufacturing range

WE CAN MANUFACTURE WELDING STRUCTURES WHICH COMPLIES TO THE FOLLOWING PARAMETERS

Dimensions

Material

Welding process

Weight

Thickness

Where we are

Highway

Station

Port

Airport